Mon – Fri: 7:00 am – 5:00 pm

Sat: 8:00 am – 12:00 pm

Here you’ll find answers to some of the most common queries about our products, services, supply and installation options, delivery times, and more.

At Showcase Plastics, we believe in keeping things simple, clear, and helpful — but if you can’t find what you’re looking for here, our friendly team is always ready to help. Just get in touch!

Search our products and categories to find exactly what you are after to complete your next project, Add these items to your basket then Submit your email to our sales team who will work out the very best market prices in real time, and offer the very best value for money on the highest quality goods available.

Simply to save you money. The costs from our manufacturers and supply chains are changing regularly so rather than saying we are the cheapest then bolting on unnecessary costs to try to increase your spend, we can work out the very best prices for the best products direct to your inbox, then you can simply, complete your order, click and collect or deliver if local.

We supply and install a wide range of building and home improvement products including windows, doors, cladding, fascias, soffits, guttering, perspex sheeting, wall & shower panels, trims, tools, locks, keys and ancillaries as well as made to measure single, double, triple glazing replacements to name just a few.

Yes! You can choose between supply-only for DIY or trade projects, or full supply-and-installation for a complete, professional service that’s stress free. Either way you don’t need an account or appointments you can just walk in, walk out and are very welcome anytime.

We mainly cover Essex and the surrounding Home Counties, but please get in touch if you’re outside this area — we may still be able to help or recommend a preferred supplier who could work well for you.

Absolutely. We offer a convenient click-and-collect service from our Maldon unit. Our address is Unit 6, Heybridge Ind Est. Maldon, Essex CM9 4XL.

Yes, we offer local delivery for all supply-only orders. Delivery options and costs will be confirmed at the time of order.

Delivery times vary depending on the product, but most orders are fulfilled within 3–10 working days. We’ll confirm exact timings when you place your order.

Yes, all of our products come with manufacturer-backed guarantees. Warranty periods vary by product — just ask us for details!

Definitely. Our experienced team are more that happy to offer advice and guide you toward the best solution for your needs and budget, it’s what we do best 🙂

We proudly supply leading brands like Liniar, Durasid, Cascade, Plaslyne, Zest, Sheerline, Kayflow and Solidor, ensuring you receive only premium-quality products covered by the best guarantees possible.

Yes, we offer a glass replacement service to refresh and revive existing windows without the need for full window replacements, drop us a call or email and our Survey Division can pay a visit to measure up and quote.

We offer a huge range including composite doors, uPVC doors, aluminium & bi-fold doors, French doors, patio sliding doors and more – for a brochure or to learn more give us a call – we will have something to exceed your needs we are confident on that!

Yes, all our windows and door products are indeed made to measure – so they fit your exact specifications, requirements and dimensions + any supply and fit installations are covered by our survey divisions guarantees.

Single glazing uses one pane of glass, double uses two with a sealed gap for insulation, and triple uses three for even greater energy efficiency and noise reduction.

Just give us a call, drop us an email, or pop into our showroom — we’ll be happy to provide a free, no-obligation quote.

Yes! Whether you’re building from scratch or upgrading an existing property, our products are perfect for both new builds and renovations.

System Specifications: Guttering:

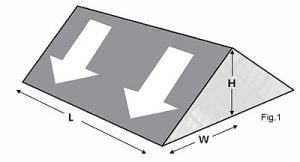

As well as normal levels of rainfall, a domestic or light commercial eaves gutter system must be able to cope with an intense rainfall event, lasting at least two minutes, that could happen once a year anywhere in the UK. The British Standard BS12056 shows how to work out the amount of rainwater (in litres per second) that could run off a roof.

Rainwater run-off = rainfall intensity (litres per second per m²) X the effective roof area (m²)

Example:

A roof has dimensions L = 2m, H = 3m and W = 4m.

See Table Below: to verify that at this flow rate the Half Round gutter would easily cope with the volume of water.

We stock Kayflow systems as our preferred supplier and different gutter styles have different flow rates and capabilities. The following flow rates are for installations with an end outlet and laid level gutter (up to 3mm fall per metre).

The roof area to be drained should always be compared with the maximum area that a gutter type is able to drain. If the figure is too low the options are to select a system with a higher capacity or increase the fall on the gutter. A third option is to move the outlet point to a central position to effectively double the gutter drainage capacity.

| Type | Height | Width | Flow Rate | Area |

|---|---|---|---|---|

| Round* | 50mm | 114mm | 0.9 l/s | 43m² |

| Square | 57mm | 117mm | 1.6 l/s | 76m² |

| Deep* | 70mm | 114mm | 1.8 l/s | 86m² |

| Ogee* | 70/80mm | 120mm | 2.2 l/s | 105m² |

| SuperDeep 170 | 108mm | 170mm | 4.3 l/s | 205m² |

All flow rates are for end outlet with the gutter laid level and have been independently established through physical testing to BS12056-3:2000.

*Standard and Cast Effect versions have the same performance characteristics.

Guide to Installation – Rainwater Systems:

Pipes:

Before commencing the installation ensure that all fascias are in good order and ready to accept the new rainwater system. Your plan will be dictated by the position of your drains. Your downpipes must be positioned directly over existing drains so mark them on your sketch.

To calculate the length of downpipe required at each drain point you need to measure from the ground to the eaves. If you have exposed brickwork you can count the number of brick courses and divide the answer by 13 to get the length of downpipe you need in metres. Remember downpipe is available in 2.5m, 4m and 5.5 metre lengths.

To calculate the length of gutter required simply measure around the building at ground level. Round it up to the nearest metre and divide it by 4 and that will tell you how many lengths of gutter you will need (as each length measures 4m).

Fascia Brackets:

Fascia brackets should be used to attach the gutter at no more than 1m intervals. So if you have 40 metres of gutter you will need an absolute minimum of 40 fascia brackets. Bracket spacing is a maximum of 1 mtr for Square and Half Round & 800mm for Deep and Ogee systems.

Fascia brackets should be used within no more than 150mm of stop end outlets, running outlets, angles, union brackets and stop ends. Use one either side of the fitting. Mark on your sketch where you will need angles to navigate the gutter round the corners.

Outlets & Unions:

On a straight run gutter lengths need to be linked with a union bracket. Union brackets need to be screwed to the fascia and a fascia bracket is to be fitted no less than 150mm either side. At the points where the gutter and downpipe meet you will need an outlet. If this happens to be at the end of a gutter length you will need to use a stop end outlet; if it is in the middle you need a running outlet. Again, use a bracket less than 150mm either side and fix the outlet to the fascia using the screw holes provided.

If you do not require an outlet at the end of a gutter run you will need to use an external stop end. Downpipe lengths are connected by pipe sockets and the downpipe should be connected to the wall with pipe clips at 1m intervals.

Offset bends can be used to angle the downpipe around eaves and other obstructions or to angle the downpipe towards a drain. They fit straight into the downpipe. If you want two separate outlets to link into one downpipe you will need to use a branch or hopper.

Setting Up:

Start by fitting the outlet directly above the drains (running outlet if it is in the middle and stop end outlet if it is at the end). Use a plumbline to check it lines up. Fix the outlet to the fascia with the 25mm No 10 rustproof screws. Bear in mind that the gutter connecting to the outlet will need to be 7mm higher at the far end (per 4m length).

Next fit the bracket fascia furthest away from the outlet ensuring you allow for the fall of 7mm every 4m length of gutter. For Example, if it’s 8m away the bracket should be approx 14mm higher than the outlet (you don’t have to be exact but tie a string line to the outlet and pull across then measure upwards).

Now tie the other end of the string line to the far bracket and attach fascia brackets at the appropriate intervals gradually sloping down toward the outlet. Repeat this process from the other side if it is a running outlet.

Brackets & Joints:

Tie the other end of the string line to the far bracket and attach fascia brackets at the appropriate intervals gradually sloping down toward the outlet. Repeat this process from the other side if it is a running outlet. Fascia brackets are to be fitted at a minimum spacing of 800mm for Ogee and Deep & 1 Mtr for ½ Round and Square. Conservatory roofs will require brackets at a minimum of 500mm to allow for snow loads. Use a union bracket if you need to join two lengths of gutter together. Simply clip the two lengths of gutter into the union bracket and screw it to the fascia. Use fascia brackets within 150mm either side.

Gutter:

Clip the gutter into the outlet first. Insert the gutter to the gutter line marked in the outlet. Now clip it into the fascia brackets by tilting it to fit under the back clip then straightening it under the front clip. When you get to a corner hold a 90o angle (or 135o) in place and mark where the gutter needs to be cut.

Cut the gutter at the required place using a hack saw and clip into the angle. Use fascia brackets within 150mm either side to support the angle. Ensure no swarf affects the seals.

At the end of the gutter run fit an external stopend and clip in gutter as previously. If your guttering needs to connect to your neighbours at the end of a run connect it with a union bracket or if it is a different type of gutter use the appropriate adaptor.

Use gutter guard to prevent leaves and other debris from blocking your guttering.

Snow Loading:

Heavy snowfalls and rapidly melting snow can cause hazards to rainwater systems especially on smooth surfaces – such as conservatories – and steeply pitched roofs.

Additional support brackets with maximum centres of 600mm will help in some circumstances but rapidly thawing snow can slip very quickly and it is unlikely that a gutter system will be able to cope with the added load or impact. The system will be able to cope with the melt-water.

BS EN 12056-3:2000 states that in areas where snow lies on roofs the front edge of the gutter should not be higher than the projected line of the roof, unless snow guards or other precautions are used. Where fixing holes are provided on fittings these must be used during installation.

Good luck with your installation, should you have any enquiries about these steps, or to arrange a supply and fit service – feel free to give us a call on 01621842000 or WhatsApp a message on +447949280147 we would love to hear from you.

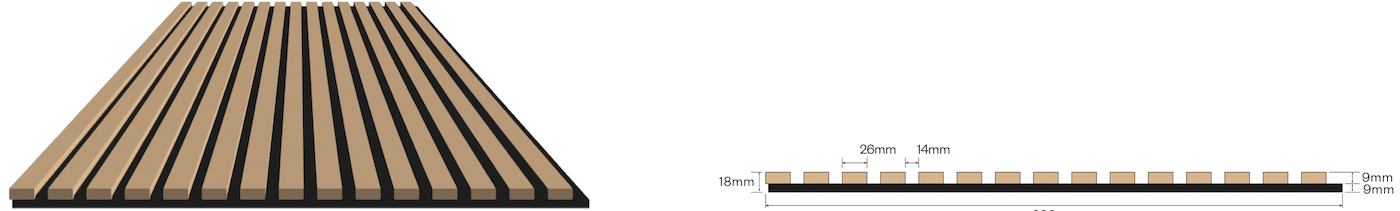

We recommend two methods for installing Zest Acoustic Wall Panels either using a grip and grab adhesive or securing the panels with screws directly into your wall.

Installing Zest Acoustic Wall Panels with Adhesive:

You will need: Stanley knife / Tape measure and pencil or marker / Adhesive and adhesive gun / Spirit level / Either a hand saw, circular saw or jigsaw all with a fine tooth blade.

1 – Prepare Your Wall:

Before attaching anything, clean your wall thoroughly to remove debris and old nails. Ensure the surface is completely flat and even for optimal results.

2 – Measure the Wall:

Measure the height and width of the area where you plan to install the wall panels. Mark the felt on the panel at these measurement points, as this is where you will cut. You will be installing the panels from left to right on the wall or from bottom to top (depending on your desired orientation).

3 – Cut Your Panels:

To cut the MDF slats, use a hand saw, circular saw or jigsaw. For a clean cut, place a strip of masking tape along your cut line. Use a Stanley knife to accurately cut the felt backing. Panels should be cut with the front face of the panel facing down (in other words the decorative side of the panel).

Measure the cut piece against the wall without adhesive to ensure a precise fit. Be sure to sand any rough edges using a 180 grit sandpaper.

Once you are confident the panel fits, apply the adhesive in a zig zag pattern on the back of the felt piece, ensuring even spacing along its length. We recommend a good quality grip and grab solvent free adhesive. Lift the panel into position (you may need assistance), keeping it straight, and press it against the wall.

Apply gentle pressure to ensure the adhesive adheres, holding it in place to allow the adhesive to set. After fixing the first panel to your wall, check the horizontal or vertical alignment with a spirit level to ensure it is straight. You are now ready to attach your next panel. Before pressing the panel onto the wall permanently you will need to make sure there is no gap between the panels and check their vertical or horizontal alignment again after each panel install.

Installing Zest Acoustic Wall Panels with Screws:

You will need: Either a hand saw, circular saw or jigsaw all with a fine tooth blade / Stanley knife / Tape measure and pencil or marker / Drill / 15 x black dry wall screws per panel 3.5mm x 35mm / (with suitable wall plugs) / Spirit level.

1 – Prepare Your Wall:

As with the adhesive installation, clean the wall thoroughly and ensure its flat and even before attaching any panels.

2 – Measure the Wall:

Measure the height and width of the area where you plan to install the wall panels. Mark the felt on the panel at these measurement points, as this is where you will cut. You will be installing the panels from left to right on the wall or from bottom to top (depending on your desired orientation).

3 – Cut Your Panels:

To cut the MDF slats, use a hand saw, circular saw or jigsaw. For a clean cut, place a strip of masking tape along your cut line. Use a Stanley knife to accurately cut the felt backing. Panels should be cut with the front face of the panel facing down (in other words the decorative side of the panel). Measure the cut piece against the wall without adhesive to ensure a precise fit. Be sure to sand any rough edges using a 180 grit sandpaper.

4 – Secure Your Panel to the Wall:

Position your panel against the wall and drill three screws every 60cm, starting about 20cm from the floor. Drill through the felt backing only, ensuring the screws penetrate the wall. After fixing the first panel to your wall, check the horizontal or vertical alignment with a spirit level to ensure it is straight. You are now ready to attach your next panel. Make sure there is no gap between the panels and check their vertical or horizontal alignment again after each panel install.

Note: Please ensure you use the correct raw or wall plugs for the wall you are screwing into, especially for walls made of old brick or less sturdy materials to provide a secure anchor for the screws.

Optional – Using Battens:

You can screw battens to the wall then screw the panels into the battens. We recommend securing the timber to the wall and then screwing the panels directly through the acoustic felt into the battens. To get the maximum sound absorption place Rockwool behind the panels between the battens. You will then achieve excellent sound absorption. This is also the ideal time to hideaway any media cables.

6 – Accounting for Obstacles – Sockets and light switches:

To accommodate plug socket and switches, measure the position on the panel and mark it on the back. Use a Stanley knife for the felt and a small hand saw for the wood slats. Sand down any exposed edges for a smooth finish. You may need to cut the panel into sections, but with proper measurement and installation, these cuts will be discreet.

For the proper installation of a plug socket or switch you will need the correct electrical box, all you need to do is install a spacer ring on an existing electrical box – this will allow for the cables to run the depth of the panel safely. The socket can then be screwed directly into the panels and wall to support the fixture.

Note: For Smaller Cut Pieces:

Our MDF slats are stapled to the felt backing at even intervals, which can risk detachment if the cut pieces are smaller. To mitigate this, ensure small pieces are cut where staples are centred on the slats. If that’s not possible, use a small amount of adhesive to secure the MDF slat to the felt backing.

7 – Installing onto Zest Acoustic Panels:

You can attach shelves, cabinets, TVs, and decorative items directly onto the panels. However, it’s important to wait 24 hours after installation before adding any items; this allows the adhesive used for the panelling to cure completely.

Ensure that your fastenings reach the substrate behind the panel, and make sure to pre-drill the holes. Drill directly into the slats. For heavier items, it’s essential to secure them by screwing through the panel and into the solid wall behind it, ensuring the weight is supported by the structural wall rather than the panel alone.

8 – Care and maintenance:

We recommend using a wood oil as it protects and keeps the natural look and feel of the wood. Once this is applied a light dusting is all that’s needed. Always use a dry cloth.

We hope you love your Zest Acoustic Wall Panels as much as we do. Don’t forget to tag us in your completed project photos on Instagram @showcaseplastics.

Good luck with your installation, should you have any enquiries about these steps, or to arrange a supply and fit service – feel free to give us a call on 01621842000 or WhatsApp a message on +447949280147 we would love to hear from you.